My goal was to turn this heavily engineered coffee grinder into something more portable while retaining it's key characteristics

Problem:

Fellow makes high-end coffee products that values precision and appearances. Their signature coffee grinder, the Ode Brew, is engineered with every feature being deliberate and serving a purpose, which is why I love it so much.

However, an issue I face is that I often don't have time to make a fresh batch of grounded coffee in the morning.

Goals:

Model a coffee grinder that achieves aesthetics and a quality that are near the levels of Fellow.

Reuse the Ode Grinder's burrs to make it more readily manufacturable

Challenges:

A portable coffee grinder is a very mechanical system, which is something I've only dealt with in a class room setting.

Product design is something that heavily interested me, combining technical and creative skills I've developed, but I have not previously made a product that required this much planning and problem solving.

Results

A fully functional SolidWorks assembly of a portable coffee grinder that kept manufacturing in mind. Meaning that it is ready for production with very minimal adjustments.

Rendered model of the Sonnet Brew Grinder

Rendering of the rotational burr grinder

Preparations

Despite how much I claim to be a coffee aficionado, anything I know about coffee is from my previous work as a barista during my freshman year.

As a result the very first thing I did before opening SolidWorks was study how coffee grinders work, especially my own Ode Grinder.

Watching repair videos I learned how the burrs are orientated, the difference between conical and flat burrs, and how the Ode feeds beans via a rotational shaft to the rotational burrs.

Sketching on loose paper I decided that it would make most sense to lay the flat burrs horizontal due being confined in a small cylindrical space, an orientation that is different from the Ode.

With a solid outline on what my journey entails, I started modeling the sonnet.

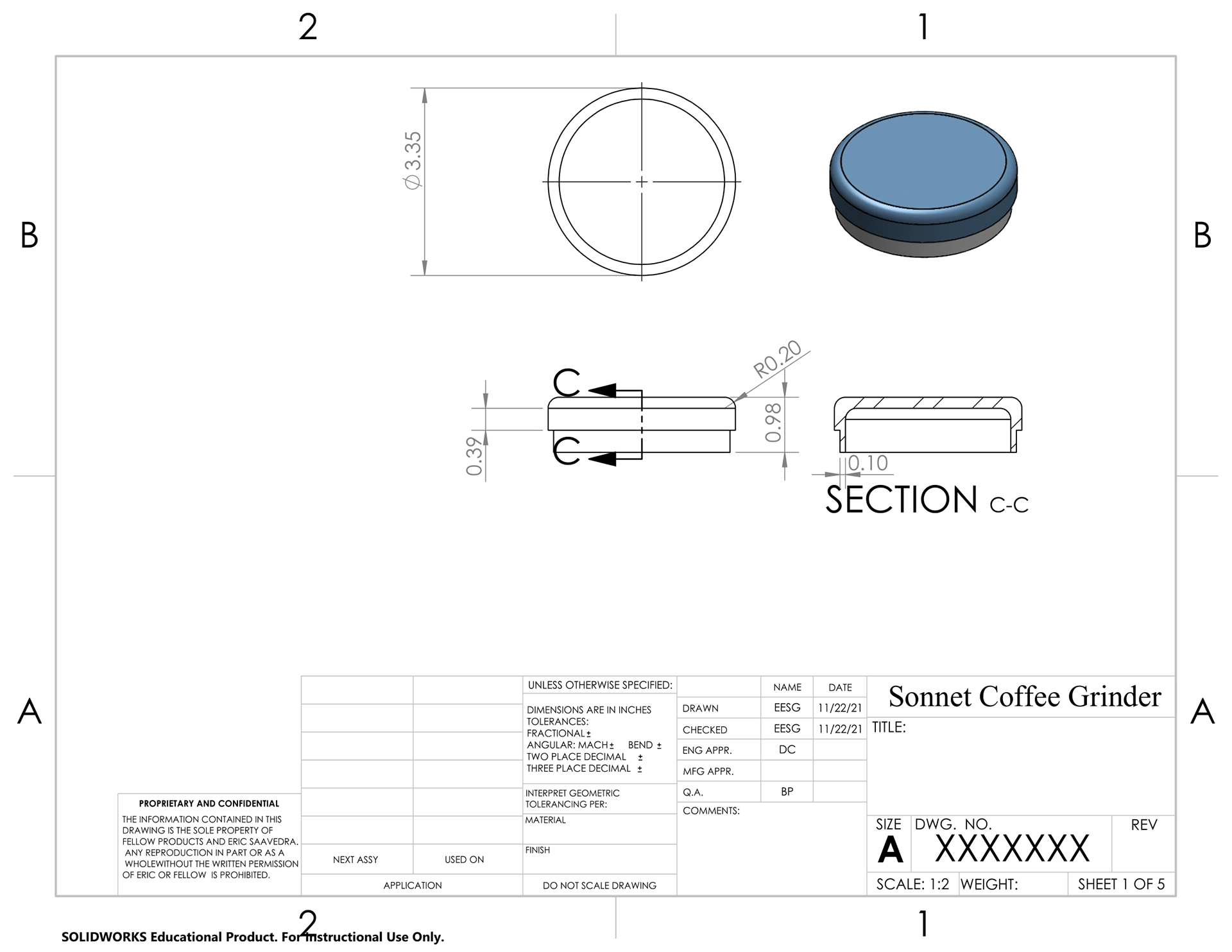

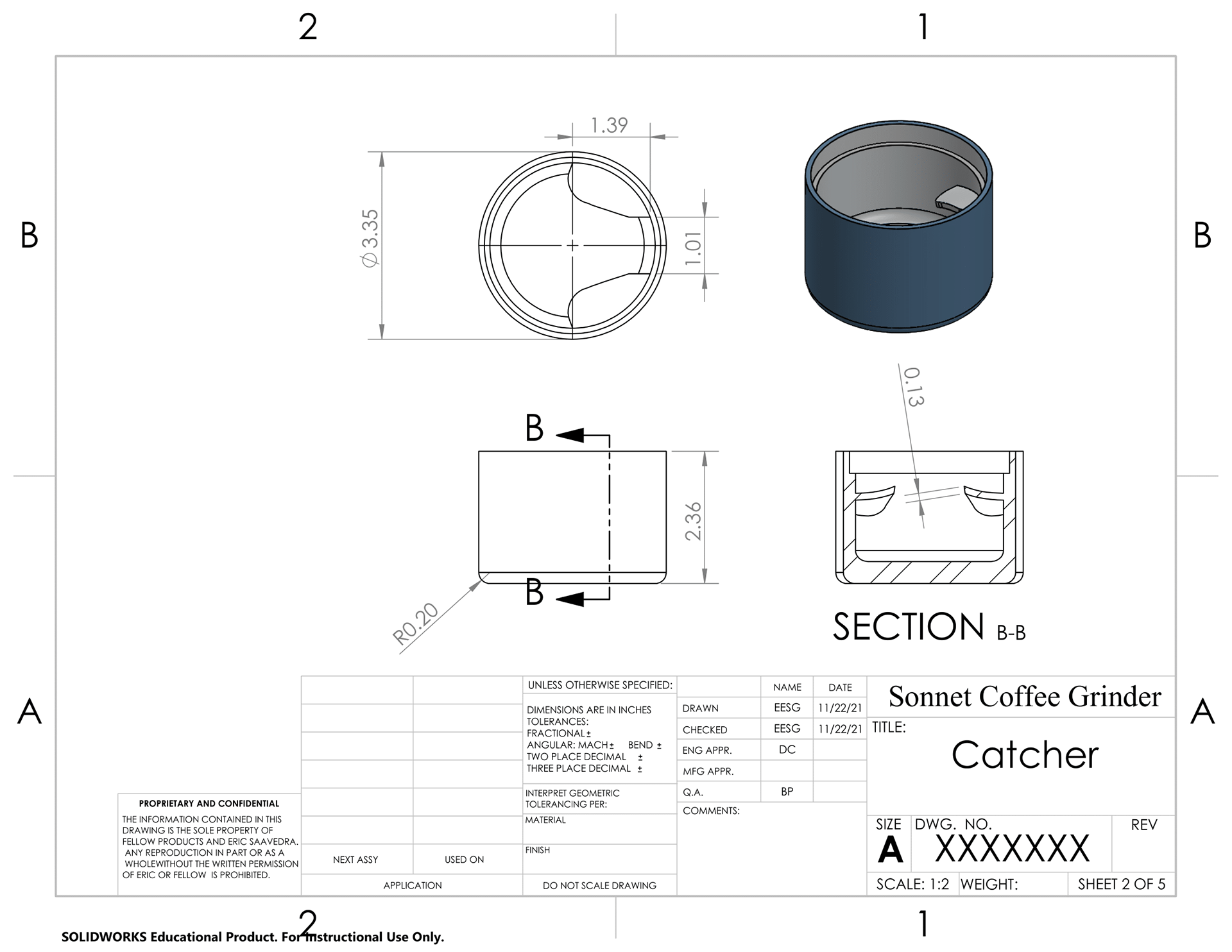

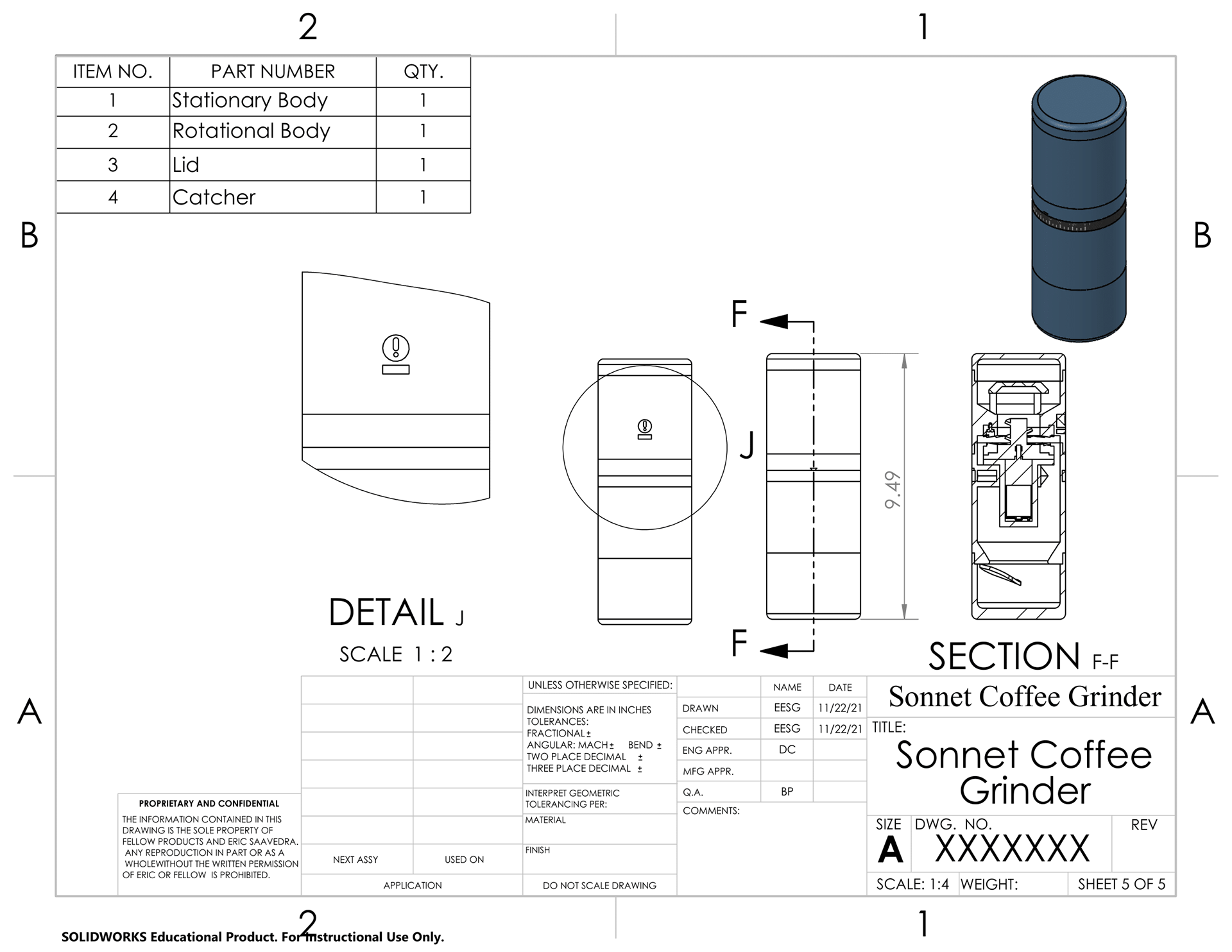

Assemblies - Lid and Catcher

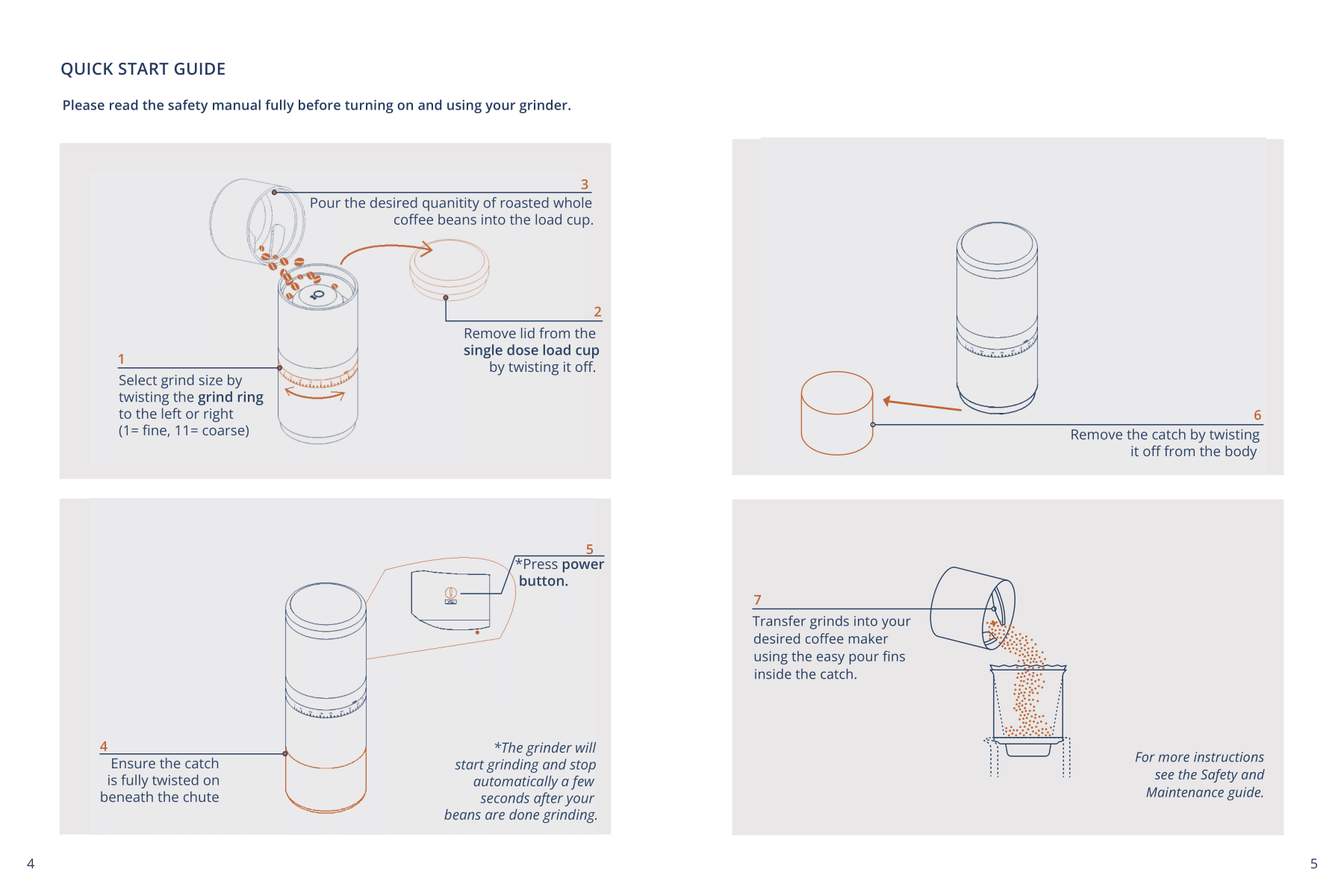

The Sonnet has 4 distinct assemblies from the perspective of a manufacture that each encompasses smaller subassemblies. From least to most complex it goes from the lid, load cup / catcher, stationary body, and rotational body.

The lid is a simple extrusion that serves as a cap for when the Sonnet that is only off when beans are getting loaded.

The load cup / catcher is a multipurpose component that can measure the serving of coffee beans and also catches them once grinded. It is also a simple extrusion that has a set of fins to help funnel the grinds into a coffee maker.

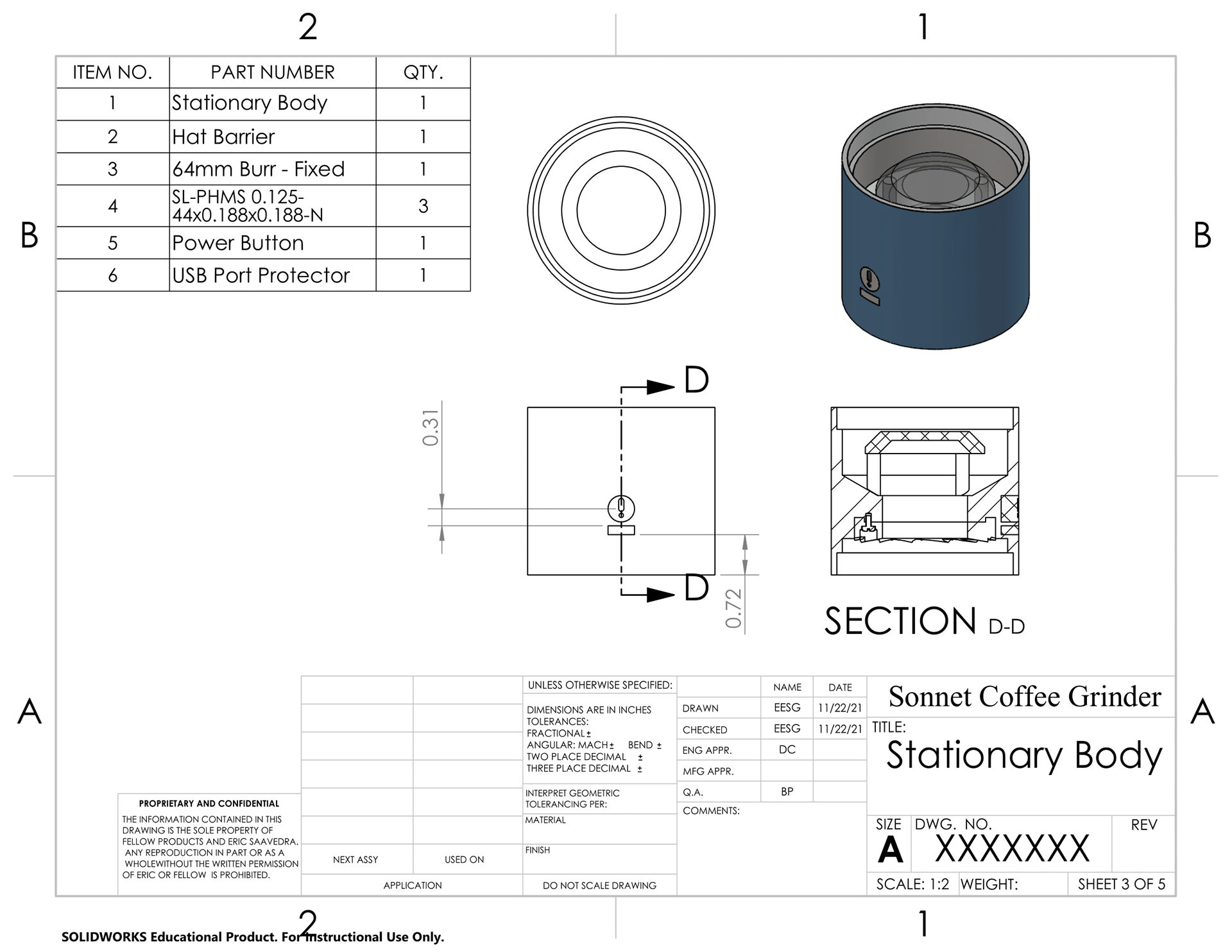

Assemblies - Stationary Body

The stationary body has the stationary burr attached on its underside (big surprise).

The coffee beans are funneled in via the chamfered top face. A protective lid is over the hole, blocking any fingers from going in while unaffecting coffee beans. The USB charging hub and power button have protective covering to protect from out door treks and are flush with the body to prevent any accidental starts.

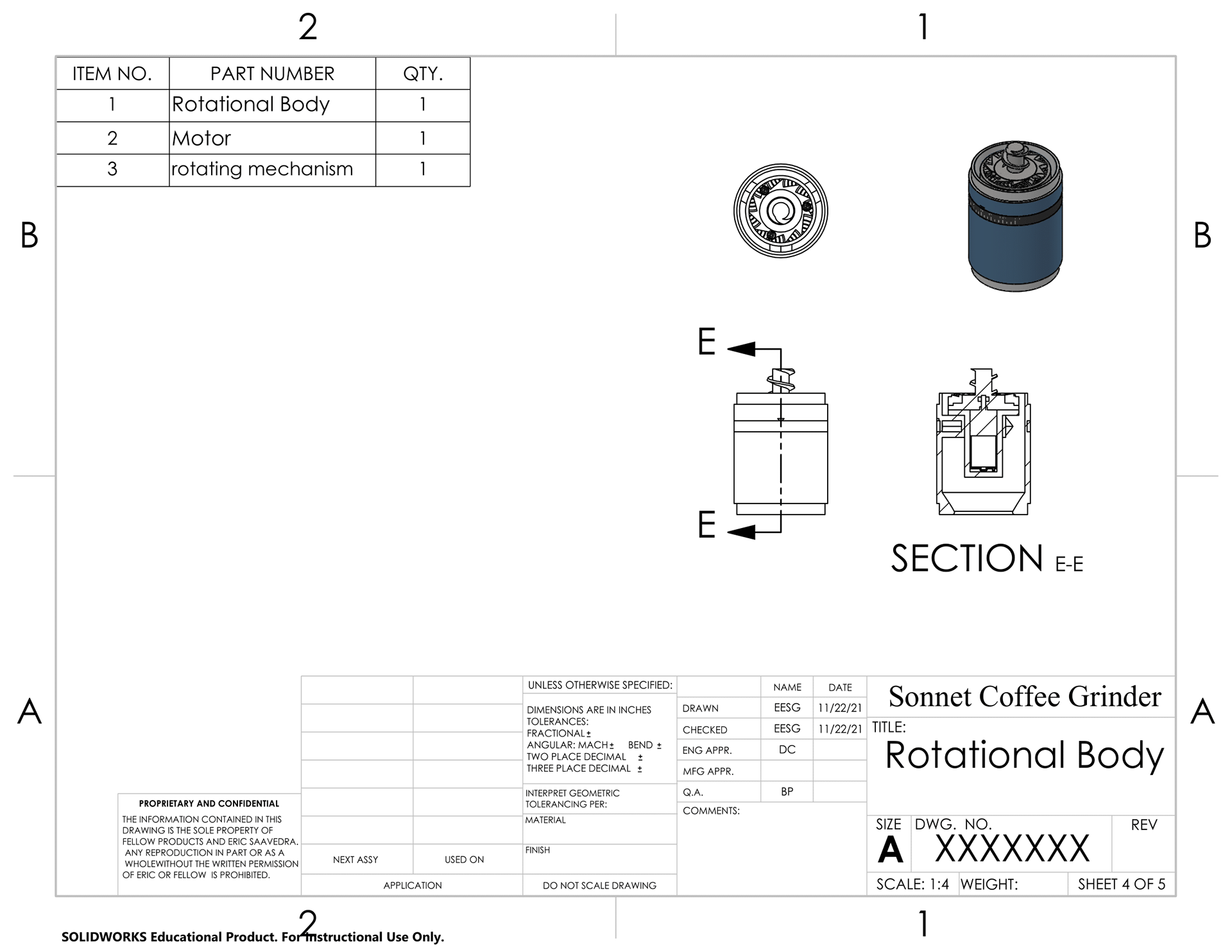

Assemblies - Rotational Body

The rotational body is supporting the motor via extruded beams from the inner walls. The beams are hollowed to pass any wires straight to the motors. The motor shaft is press fitted to the rotational burr and held with a spring mechanism. A ring dial is flush with the body and adjusts the grind setting when twisted. Once grinded, grounds fall to the lower chamfered face where it slides in the catcher.

Final Design

With a volume that is only 22% of the Ode Brew Grinder, the Sonnet is a portable coffee grinder that durable and powerful enough for any coffee aficionado .

W x H: 3.35' x 9.49'. Could comfortably hold the body of the Sonnet while either twisting the grinder ring, the lid or catcher, or scooping in beans. Capacity of 4 servings (80 g) of coffee beans.

Future Areas of Exploration

Experimentation with burr configuration to conserve space. This can be with small burr sizes or moving to a horizontal system similar to the Ode.

Reduce calculated weight by applying material to only certain layers of model.

Manufacturing a prototype with workings mechanism's

Optimizing choice of motor.

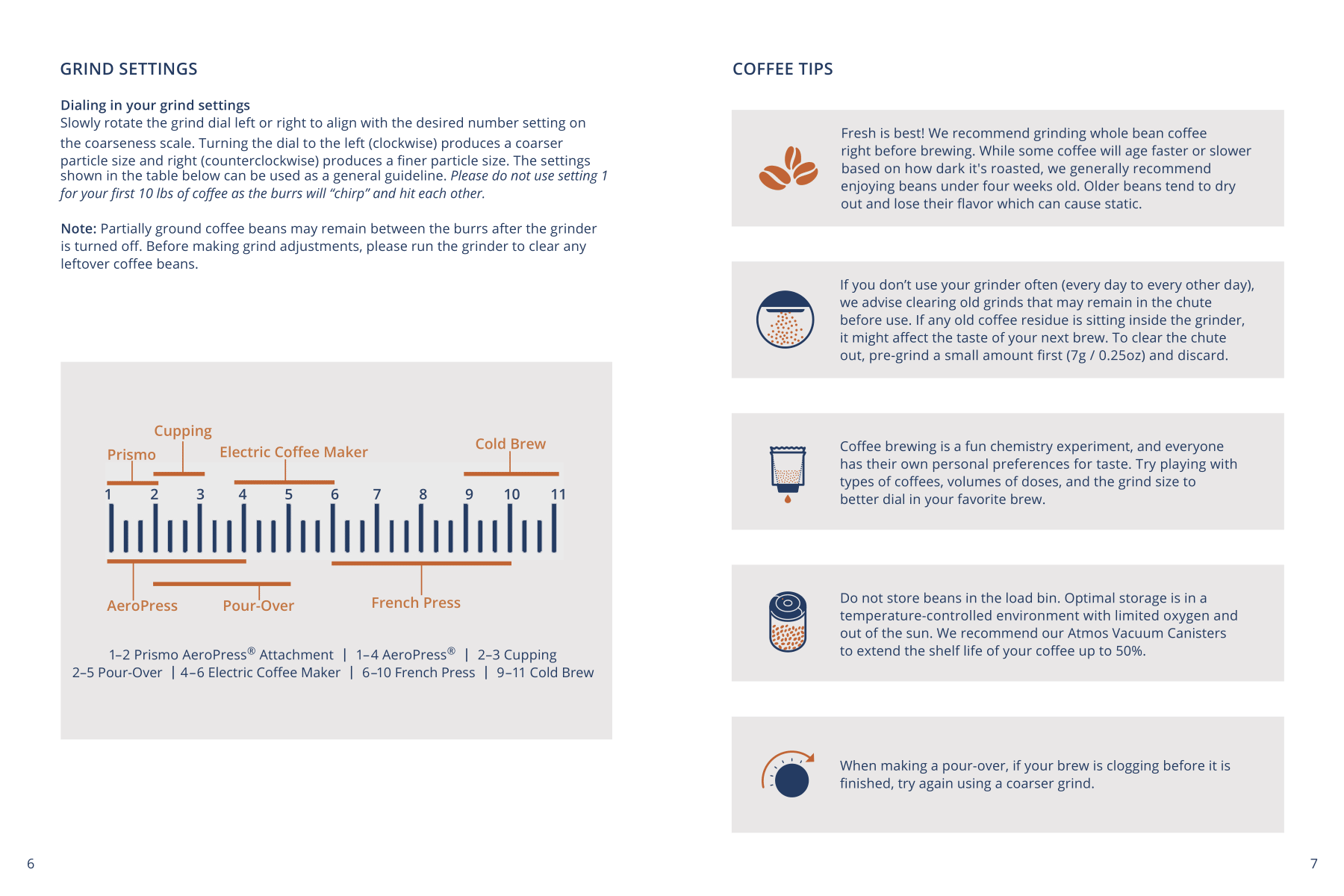

Manual

Below is a mock manual of the Sonnet Brew Grinder. The aesthetics of even the packaging and instructions is something Fellow devotes time to, which is another way I tried to mimic their personality.

Engineering Drawings

Below is engineering drawings of the Sonnet Brew Grinder. Dimensioning are shown and features that are harder to see are exploded to visibility.

Miscellaneous Photos

Below is a collage of miscellaneous photos that better showcase small designed features as 3D models. Not rendered due to the fact my laptop lacks the power to do so for so many.

Image of spring mechanism

Image of hallowed out beam